VAE for Blade Design

The use of AI-based ROM with engineering data is indeed powerful and in the ‘ai spotlight’, but I think the use of autoencoders is also revolutionary and gaining visibility.

A few inherit benefits:

Provides a new parameterization you may not have realized from traditional means. They provide highly 3D and ‘abstract’ changes of the design.

Allows you to specify however many (or few) parameters you wish to have to recreate your geometries (e.g. my last study i used 7 parameters).

Can generate your geometry in an ‘inverse design’ capacity

Rapid design optimization tasks are possible when using machinelearning models instead of simulations (e.g. my last time took 90 seconds).

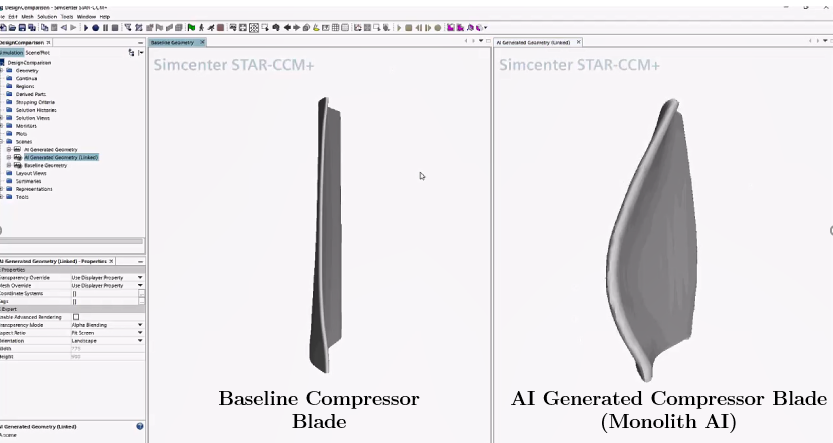

In this project, a combination of CAD files and CFD results were used to make a variational auotencoder. The encoder can recreate any of the CAD geometries by use of its own parmaeterization (a latent space, where the user can specify how many parameters are desired). A neural network is stacked thereafterwards, whereby learning the relationship between the latent parameters (geoemtry) and the CFD results (performance). This neural network is used in an optimization loop, which quickly (in about 90 seconds) identifies values for the latent parameters which most satisfies the cost function (maximizing aerodynamic efficiency). Once the optimum latent parameters are identified, the CAD is re-created via the decoder. That is what is pictured herein.